North Haven, CT (April 17th, 2017) – Precision Combustion, Inc. (PCI) announced it has been awarded Department of Energy (DOE) Phase IIA Small Business Innovation Research funding to develop a long-sought direct method to convert shale-gas methane into ethylene or fuels in a direct and compact process. This new shale-gas to fuels process offers environmental and economic benefits while utilizing abundant domestic natural gas resources.

North Haven, CT (April 17th, 2017) – Precision Combustion, Inc. (PCI) announced it has been awarded Department of Energy (DOE) Phase IIA Small Business Innovation Research funding to develop a long-sought direct method to convert shale-gas methane into ethylene or fuels in a direct and compact process. This new shale-gas to fuels process offers environmental and economic benefits while utilizing abundant domestic natural gas resources.

PCI’s approach offers substantial energy savings with significantly reduced process complexity and capital intensity, as compared to industrially practiced large-scale indirect routes which include methane-steam reforming, followed by water-gas shift, and then methanol synthesis or Fischer-Tropsch upgrading.

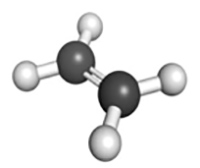

PCI’s simpler and less costly path to liquid fuels and chemicals involves a new approach to oxidative coupling of methane (OCM). An effective OCM process will enable sufficiently high yields of ethylene to allow for economic production of a wide range of hydrocarbon products using existing ethylene processing technologies, including the established olefin to gasoline process.

According to Dr. Weissman, PCI’s Principal Scientist and the project leader, “Our integrated process combines alkane activation via OCM to form ethylene while optimizing a unique reactor design, catalyst and process understanding specific to our approach. Using a combination of bench-scale experimental studies, detailed reaction mechanism modeling, and process development, we have demonstrated that our process can overcome oxidative over-reaction to combustion products while reducing reaction rate limitations. We overcome the inherent limitations of OCM while maintaining catalyst effectiveness.”

During the course of the predecessor SBIR Phase II project, PCI identified aspects of the catalyst composition most important to the effectiveness of the process and identified key aspects that impact ethylene production.

Kevin Burns, President of PCI, adds “We have demonstrated the core of a breakthrough here. In Phase IIA we are improving reactor performance and catalyst design, and looking for interested partners for participation. The outcome will be an economic and scalable new reactor approach to upgrading shale gas to ethylene and other chemical intermediates.”

In the Phase IIA program, PCI plans to have a completed design and operating specifications to enable a pilot-scale demonstration of the CMT reactor technology for the ethylene synthesis component of a shale-gas to gasoline or chemicals project. Success would simultaneously cut the costs of transportation fuels while also improving American energy independence and reduce greenhouse gas emissions. This offers to boost the value of the shale gas between $1 to $4/MMBTU, above the current wholesale value of about 3.6 $/MMBTU.

Precision Combustion, Inc. is a clean energy technology company developing and manufacturing catalytic devices and systems for energy sector applications. To learn more, visit precision-combustion.com.

For more information, contact: Tony Anderson

Director, Marketing and Business Development

203-287-3700 ext. 290

aanderson@precision-combustion.com