Precision Combustion, Inc. (PCI) is developing air cleaning applications focused on control of Volatile Organic compounds (VOC’s), Sulfur and other air pollutants. Applications include air treatment systems for spacecraft, submarines and collective protection shelters. These reactors include temperature and pressure swing adsorption/desorption approaches. They consist of resistively heated substrates coated with sorbents. Standard sorbents (e.g. zeolites) are coated on the substrates and are regenerated by various combinations of heating and pressure swing.

Air Cleaner Performance Benefits

- Ultra-compact size and low weight

- Direct electrical heating of the conductive substrate utilizing low power

- High energy and conversion efficiency

- Reduced maintenance and power requirements

- Improved durability for long term reliable operation

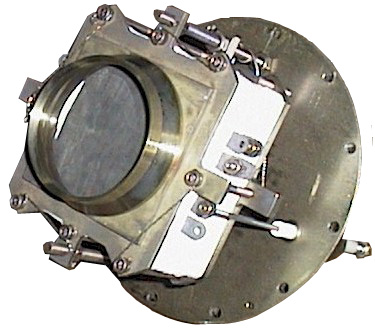

The technology has been developed in two embodiments, a Trace Contaminant Oxidizer for VOC’s and CO and a Trace Contaminant Adsorber for CO2 and other Spacecraft Maximum Allowable Concentration (SMAC) compounds.

Additional Papers on Pci’s Air Cleaner Technology

“Unique Metal Monolith Catalytic Reactor for Destruction of Airborne Trace Contaminants.” SAE 972432.

“Demonstration of an Ultra-Short Channel Metal Monolith Catalytic Reactor for Trace Contaminant Control Applications” SAE 1999-01-2112.

“Performance Characterization of a Prototype Ultra-Short Channel Monolith Catalytic Reactor for Air Quality Control Applications.” SAE 2005-01-2868.

Contact PCI to learn more about how our solutions may be adapted for your needs.