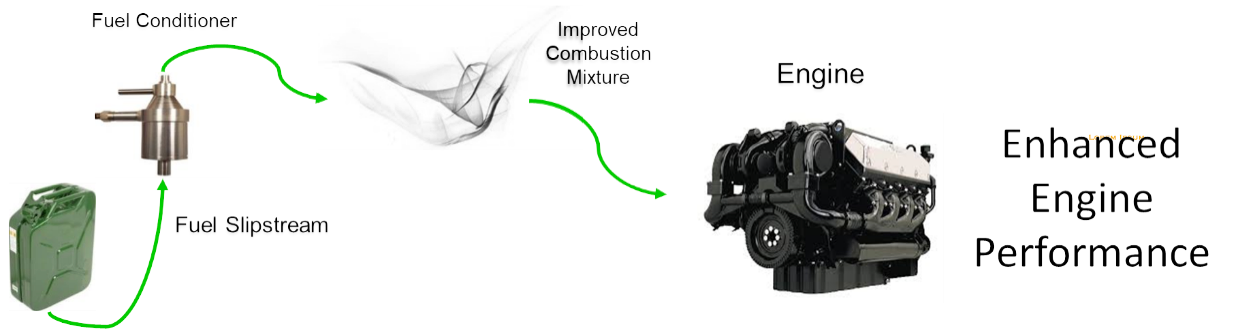

PCI’s Internal Combustion Engine system takes a slipstream of incoming fuel and creates a high octane, highly combustible mixture that is injected into the engine with standard fuel. This method positively impacts engine performance, reduces emissions and enables improved engine efficiency. PCI’s engine augmentation has proven performance on both spark and compression ignition engine systems.

Benefits

- Improved combustion stability (lower coefficient of variation (COV) in indicated mean effective pressure (IMEP))

- Lower COV of IMEP with H2 up to 75% reduction

- Significantly extended dilution limit @ low COV

- Improvement in Break Specific Fuel Consumption (BSFC)

- Higher power

- H2/syngas augmentation increases peak Brake Mean Effective Pressure (BMEP)

- Lower emissions

- Significant reduction in NOx, HC, CO, PM

- Lower brake-specific NOx up to 50% reduction

- Lower brake-specific HC up to 50% reduction

- Lower brake-specific CO up to 40% reduction

- Reduction in Required Ignition Discharge Energy

- Reduced emissions at cold-start

- NOx reduction at steady state

- Faster combustion:

- Reduced ignition delay enabled 7 – 16 degrees of spark advance

- Lean tolerance:

- Internal + External Dilution up to 77% increase Tolerance

Contact PCI to learn more about how our solutions may be adapted for your needs.