PCI is developing oxy-fuel combustion technology for use with applications in gas turbine power cycles, coal powered plants, and production of methane hydrates as well as enhanced oil extraction applications.

The need to keep pollutant emissions at ultra-low levels, increase power plant efficiency, and provide a path forward for carbon capture has led to the development of oxy-fuel combustion in both pulverized coal plants and turbine power cycles for its promise of elimination of nitric oxide (NOx) emissions at the high combustor temperatures required for efficiency. This is achieved through burning fuel with pure oxygen yielding only carbon dioxide and water in the exhaust stream. This offers the potential for simple carbon capture and sequestration (condensing the water leaves a pure CO2 stream).

In addition, for methane hydrate and enhanced oil recovery, oxy-fuel combustion (performed downhole) provides lower compression cost operation compared to air-fired tools.

PCI’s Streamlined Zero Emission OXY-Fuel Reheat Combustor

A reheat combustor is a critical component in oxy-fuel systems to boost cycle efficiency. Additional energy input between gas turbine stages raises mean temperatures, increasing output and improving efficiency. Current high efficiency concepts for oxy-fuel power generation include multiple sequential turbines for expansion of the working fluid allowing staging of heat input and thus greater efficiency. A reheat combustor integrates with this oxy-fuel cycle and increases the temperature of steam/CO2 mixture entering intermediate pressure turbines. This increases output power and improves efficiency without increasing peak cycle temperatures. PCI’s streamlined zero emission oxy-fuel reheat combustor is uniquely designed for the aggressive combustion environment in the harsh steam/CO2 exhaust expected in the cycle and is capable of operating with high stability and complete combustion

Attributes of OXY-Fuel Reheat Combustion

- Critical component in oxy-fuel systems to boost cycle efficiency

- Reheating improves steam quality entering the low pressure turbine

- Oxy-fuel system offers potential for high efficiency cycles and near 100% carbon capture

- Eliminates expensive CO2-separation units and exhaust stack clean up leading to cost savings

- Uses pure oxygen hence no NOx emissions

Benefits of OXY-Fuel Reheat Combustion

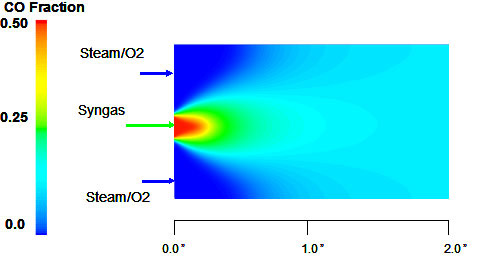

- Rapid mixing within two inches from injector exit with < 5% unmixedness in 1-2 ms (Figure 1)

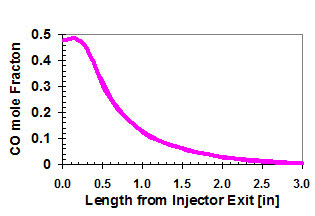

- Near equilibrium CO levels within 3” from injector exit with no excess O2 (Figure 2)

- Well stabilized complete combustion with syngas and steam with no unburned fuel

- Robust and compact design

Figure 1.

Oxyfuel Combustor System Allows Rapid Mixing ( < 2 inches)

of Fuel/Oxidant Allowing Highly Efficient and Short Combustors

Figure 2.

Carbon Monoxide Emissions at Equilibrium Values Within 3 inches From Exit of the Injector

Commercial Applications and other Benefits

Success with PCI’s novel approach to oxy-syngas combustion will lead to commercialization of the combustor for the reheat cycle which will help enable use of coal for clean power generation through IGCC combined cycles. The technology offers a major component solution as part of development of zero-emissions technology for coal combustion while offering the potential for carbon dioxide sequestration.

In addition, the technology provides a compact technology solution for production of methane hydrates and enhanced oil recovery applications.