Microlith ® Technologies

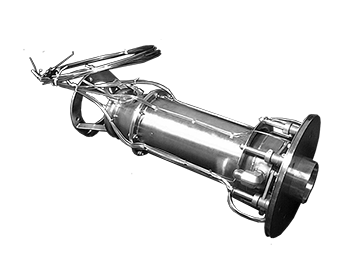

PCI has developed a compact, lightweight and highly efficient catalytic reactor design offering major performance and cost advantages when compared to conventional state of the art catalytic reactors.

PCI’s patented Microlith® technology consists of a series of discrete, ultra-short channel length, metal monoliths with low pressure drop. This combined with our advanced catalytic coating technology enables the simultaneous design of a high cell density, low thermal mass device and smaller, lighter and higher efficiency catalytic reactor. Both mass transfer and heat transfer are significantly increased by the substrate design, allowing more rapid reactor response to gas temperatures as well as improved rates of reactant contact with the surface.

Advantages

Microlith® technology offers superior attributes, major performance benefits and cost advantages when compared to conventional state-of-the-art catalytic reactor systems.

Oxidizers

- Ultra-compact: equivalent conversion and the same pressure drop as a monolith substrate with a 20-fold size reduction

- Lightweight: Typically 10 times lighter than competing technologies.

- Fast transient response: Typically 30 times faster than ceramic monoliths

- High geometric surface area: Up to 6 times higher than competing technologies, leading to higher reaction selectivity and performance advantages.

Additional Articles

Additional information can be obtained from the following published papers:

“Development and Performance of Microlith® Light-off Preconverters for LEV/ULEV”, 1997 Society of Automotive Engineers, Inc.

“Laboratory Evaluation of Ultra-short Metal Monolith Catalyst”, 1998 Society of Automotive Engineers, Inc.